FlackTek™ & SynergyMixers are exhibiting at silicone™ EXPO EUROPE

Visit us on 24th & 25th February 2026

FlackTek™FlackTek™1,918 followers1,918 followers

Contact us• Visible to anyone on or off LinkedIn

FlackTek™ just leveled up. 🦾

We’re excited to share that FlackTek has officially joined Graham Corporation, marking a big step forward in how we scale, support, and advance high-precision materials processing.

What doesn’t change:

🌀 Our people.

🌀 Our technology.

🌀 Our obsession with doing mixing better.

What does change:

🌀 Our ability to move faster, reach further, and support customers globally, without compromising the performance and repeatability they depend on.

Our bladeless mixing technology was built to solve problems traditional approaches struggle with: long cycle times, inconsistency, air entrapment, and downtime between batches. Just as important, our team brings deep processing expertise and hands-on support to help customers dial in their process, not just install equipment. The result is a fundamentally different way to approach materials processing, one that improves material integrity while enabling higher throughput and scalable factory flow.

As part of Graham, we now stand alongside vacuum, thermal, and high-speed rotary technologies, adding a third pillar to an already strong offering and bringing advanced materials processing into the mix.

FlackTek will continue to operate with the same vigor and focus on solving customer challenges. We’re just doing it now with a stronger arsenal for what’s next.

Bladeless mixing isn’t an upgrade.

It’s a shift in how production gets done.

This is the future of materials processing.

Full press release:

https://lnkd.in/g5fw9Xcr

As a key market for PST it’s always good to keep up-to-date with the latest technologies and developments.

Exhibiting and introducing the 3D Printer from Lynxter; we sell both the materials and the equipment.

We were also joined by Synergy, demonstrating their mixer technology for mixing and degassing silicones and other materials.

As always it was a great opportunity to hear about exciting new developments, meet new and old contacts.

Thank you to all who came to visit our stand.

Bringing Ideas, Materials, and Possibilities for the Silicone Industry.

FlackTek™ will be demonstrating an advanced tool for mixing, grinding, milling and dispersing. This Non-Invasive Mixing™ technology can be used to process any combination of powders, pastes, putties and liquids from 1g ‑ 200kg+. The FlackTek™ removes air bubbles while homogenizing the sample, in seconds, and ABSOLUTELY NO CLEANUP!

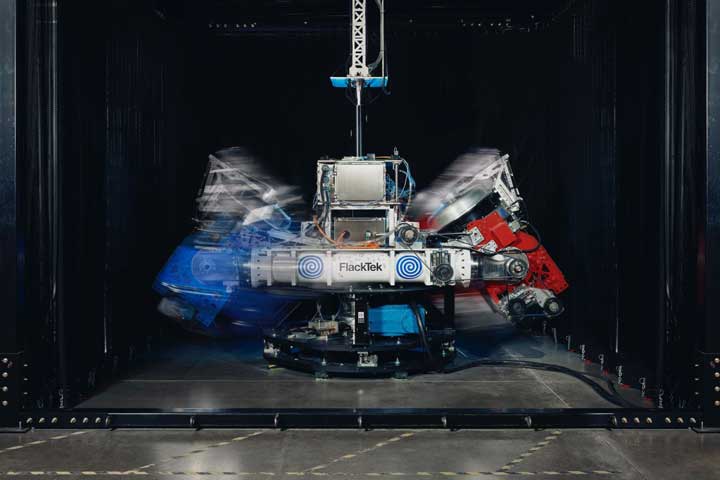

Anduril Industries on Thursday 3rd October 2024 said it has partnered with FlackTek to develop and manufacture a new large-scale system that rapidly mixes propellants for solid rocket motors (SRMs), saving time, real estate, and dramatically boosting production to meet increasing demand…

As posted on: https://www.defensedaily.com/

Anduril Industries and FlackTek Partner to…

Revolutionize Solid Rocket Motor Production!

We are thrilled to announce our groundbreaking partnership with Anduril Industries to develop the world’s most advanced mixing machine, the Mega FlackTek – also known as “The GOAT” – in Boulder, CO.

This partnership highlights FlackTek’s ability to deliver mission-critical capabilities across high-tech industries, solidifying our role in shaping the future of large-scale manufacturing.

Get more information at: https://lnkd.in/g7Sz5QKS

Synergy Devices Limited move to a new web site for the sale of FlackTek DASD™ – Dual Asymmetric Servo Drive Mixers and Accessories.

The DASD™ is the most advanced mixing technology available today, fully capable of mixing a variety of materials from thick to thin in any combination quickly and repeatably.

The DASD™ eliminates air bubbles and mixes in disposable containers. It is used to mix colloids, fluids, powders, pastes, creams, grease, resins, inks, paints and silicone mixtures.

Lab size small batch manufacturing mixers have the capacity to mix in samples in seconds. Sample sizes range from 1 gm – 20 kg and can be mixed in cups and cartridges, including Semco. Absolutely no cleanup required.

Director at Polymer Systems Technology Ltd

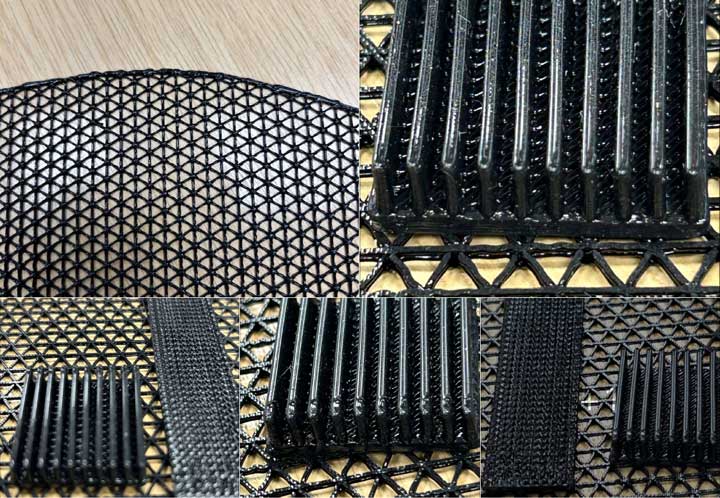

3D printing PST-4943 and PST-2631 static dissipative RTV or heat cure silicones have evolved.

These materials perform better from the process of 3D printing than conventional moulding achieving less than 100 ohm-cm resistivity.

Creating matrices, objects and complex geometries for RFI and EMI shielding. Ideal for bespoke conductive gaskets and can be adhered to multiple substrates.

The benefits include reduction of weight, typically with 3D printing the infill can be between 30% to 100% and still provide the low resistivity.

Conventional moulding would always be a 100% infill , therefore the possibility of reducing weight in a multitude of aerospace and defence applications using silicone 3D printing.

A medical version is also available providing cytoxticity testing results.

These materials typically have a durometer of 45 shore A. Elongation of 275% with a tear strength of 50 ppi.

Visit our application laboratory and check out our pioneering technology and take advantage of our bespoke silicone 3D printing training.